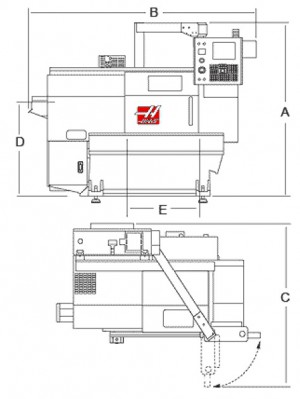

GT-20 DETALS one machine

The compact GT-20 takes up only 8' x 4.5' of floor space, yet offers a generous 11" (279mm) x 12" (305mm) maximum capacity. The machine provides a maximum part swing of 13" over the front apron, with an 9.25" swing over the cross slide. The X axis provides 6" of travel with 2400 lb of thrust, and the Z axis provides 12" of travel with3700 lb of thrust. Rapids are 710 ipm in both axes.

The Haas-designed, 20-hp (peak) vector dual-drive system gives the GT-20 spindlespeeds up to 4000 rpm (with hydraulic chuck option), and peak-torque of 154 ft-lb. On-the-fly wye-delta switching delivers higher torque and a wide constant-power bandfor constant surface speed cuts.

The base configuration of the GT-20 has a maximum speed of 3000 rpm, and does not include a chuck, hydraulic system or tool turret. The machine’s A2-6 spindle nose has a3" bore and accepts a variety of optional through-hole chucks and collets. The cross slide accepts gang-style tooling. The Haas control features advanced tool management, single-button features, 15-inch color LCD monitor and a USB port.