VM-03 DETALS three machine

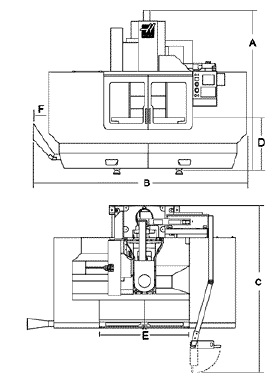

Designed specifically for mold makers, the VM-3 is a high-performance machine featuring a generous 40" x 26" x 25" work cube, a 54" x 25" table, a 12,000-rpm spindle powered by a 30-hp vector dual drive system, and a high-speed control with full look-ahead. The 40-taper spindle uses a unique inline, direct-drive system that couples the motor directly to the spindle rather than using belts (which are a major source of heat). The result isless vibration, less heat and less noise – which means excellent surface finishes,extreme thermal stability and quiet operation.

The VM-3’s 54"x25" cast-iron table features standard T-slots (13 in the Y direction and 6 in the X) as well as an array of drilled and tapped holes. It has a maximum weight capacity of 4000 lb. The VM-3 comes standard with a 24+1 side-mount tool changer

that swaps tools in 2.8 seconds. Also standard are an automatic chip auger system, programmable coolant nozzle, remote jog handle, automatic air gun, high-speed machining software with look-ahead, hard drive with Ethernet interface, floppy drive, Visual Quick Code programming, user-definable macros, coordinate rotation & scaling, spindle orientation and power failure detection module. The Haas control features advanced tool management, single-button features, 15-inch color LCD monitor and a USB port.

Available options include linear scales, Visual Quick Code probing and expanded program memory (up to 16 MB).